Prepress Center, a printing company headquartered in Hokkaido, was in charge of producing this jacket. A report on how to make a jacket that pays close attention to details such as the specifications of the tray and the CD case. He also asked the perspective of a local company.

Checking the proof print with a magnifying glass

Meeting on improvement of tray part

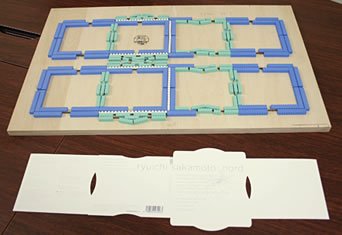

Complicated CD tray and its die

Confirmation of completed tray

Place the tray in the CD case

CD tray and its die

For this jacket, we paid particular attention to the following two points.

1. Commitment to the outer case

The foldable shape does not use glue and is environmentally friendly. The jacket hidden inside allows you to check the printed contents by unfolding the case. Developed by applying the shape of the desk calendar case that we manufacture and sell every year.

2. Commitment to paper

We have adopted eco-friendly paper that contains 50% or more sawdust, which is attracting attention for its use in biomass.

-For the production of this regional CD

When I first talked to you, I felt the joy of being able to help Sakamoto-san, a world-class musician who is also engaged in environmental movements, and the anxiety of being able to deliver satisfactory quality. It was full. However, let's hear the concept that this CD is a song made for Hokkaido, and let's collide with the maximum power we can show! I decided to prepare.

-What are the disadvantages and advantages of having a head office in a rural area (Hokkaido)?

Originally, it was a dream to establish an economy locally.

Hokkaido has no major industries other than primary industries, so it cannot be said that it is a blessed condition. However, I believe that there is no regional disparity in terms of “technology” or “will”, and I believe that with technology, we can overcome the local handicap.

Hokkaido seems to have a long travel distance, but the travel load is much smaller than that for imports. Given the current situation in Japan, where most of the goods are procured as imported goods, I think Hokkaido can contribute to the construction of a next-generation society as a production base for various fields.

―In light of that, are there any specific efforts you are focusing on?

Printing is a resource-consuming industry. Therefore, we are trying to put in place a system that enables us to produce half the amount of CO2 emitted within five years. In addition, although we currently rely on overseas pulp, we believe that domestic pulp can be utilized if domestic forest maintenance progresses, so we have been working with NPOs since last year to create forests through tree planting and thinning in Bihoro Town, Sobetsu. I started in Sapporo, Japan.

We will promote forests in Hokkaido, which accounts for 1/4 of Japan, in cooperation with the local community so that forest materials produced from them can be used for pulp in the future. In addition, we aim to become a pioneer company in the environment and continue to support activities that enable the economy to rotate in a regional circulation type.

We are thinking that we can collaborate with more Trees.

"Nord"

¥700 (tax included)

[CD single]

Release Date: April 15, 2009

Limited area sales only in Hokkaido,

This is a limited edition version.

* There is no sale on commmonsmart other websites.